Last we shared of the pool house was the addition of the batten strips and framing out the vent hood. Certainly progress, but there’s one big step to cross off the list before the walls can be completed. Tiling the entire floor, or roughly 600 square feet. Dun dun dunnnnn. Though I have the easiest part of the process, carrying/opening boxes of tile, I was dreading this step.

We know from framing the walls that nothing is square in here, with the floors sloping up to two inches over the length of the space. Luckily, not much phases Ben and on Saturday, he jumped right in.

For a continuous feel, we’re using the same slate tile and herringbone pattern as the kitchen.

One small difference is slightly wider grout lines. Knowing the floors are a touch uneven, we decided on 3/8 inch grout lines (versus 1/16 inch in the kitchen) to help minimize discrepancies.

Working around the pool proved trickiest, until Ben built himself a marking jig. Scraps of plywood set to the depth of the pool lip with a screw slightly through the top piece.

Working around the pool proved trickiest, until Ben built himself a marking jig. Scraps of plywood set to the depth of the pool lip with a screw slightly through the top piece.

The bottom strips slide along the inside edge of the pool, with the screw scoring the top of the tile, marking where to cut.

At the end of tile day one, Ben got roughly 1/4 or 1/3 of the space done.

The next morning, the tile had set so we pulled out the spacers. I followed up by washing the tile, scrubbing off any extra mastic.

Obviously, grout is still to come.

Having this tile in various rooms throughout our house, we know this tile is durable and the texture is naturally slip-resistant.

Dark floors paired with (what will be) white walls will ground this bright space.

We still have at least several days of tile or tile related tasks in our future, but progress always feels good.

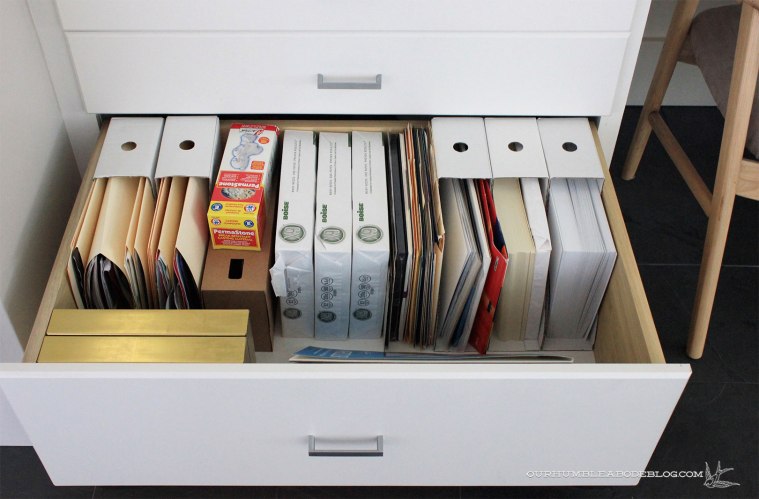

As an extension of the kitchen, we remodeled the office along with the kitchen. Deep, wide drawers make organizing any room a dream, and I quickly filled each one up as soon as the office was functional again.

As an extension of the kitchen, we remodeled the office along with the kitchen. Deep, wide drawers make organizing any room a dream, and I quickly filled each one up as soon as the office was functional again.