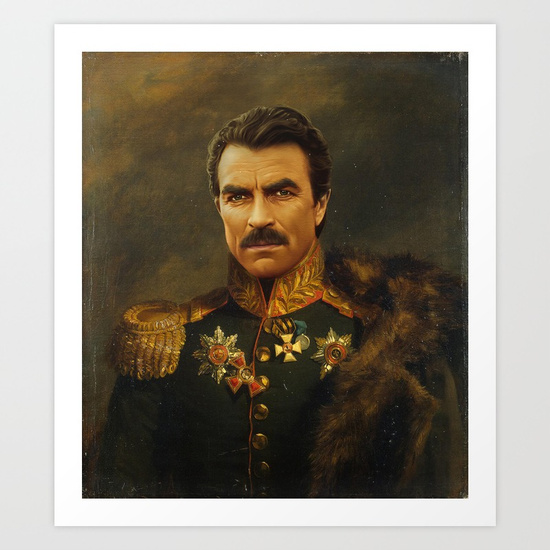

Happy New Year, everyone! I hope you all had happy holidays. We had several visitors, a mountain of snow (which meant Ben spent most of his time off working), and plenty of time relaxing at home. Our original plan included knocking out a good chunk of work in the pool house, but snow changed those plans. Instead, we had little project time, but in that time, we finally built a frame for the Tom Selleck Replace Face print I’ve had for a year.

It’s a non standard size, measuring 28 by 32 inches, so store-bought options don’t work. Instead, it sat in a cabinet until now, when we built a walnut frame. Using a leftover walnut plank, we started by cutting four 1.75 inch strips to create the thickness of the frame. With the strips cut, we ran each piece through the table saw twice to notch out the sides for the plexiglass, print, and backing to rest inside.

To attach the pieces together, we glued each corner, then shot 1 inch long pin nails from each direction. They’re tiny and only noticeable up close.

In lieu of real glass, we used a 30 inch by 36 inch sheet of plexiglass. Slowly feeding the sheet through the table saw cut like butter, without shattering, as I had pictured in my head. A sheet of 1/4 inch MDF serves as the backing, sandwiching the print between, keeping it in place.

The print hangs in the theater room, directly in front of the room entrance. I adore the combination of deep greens and walnut.

Tom Selleck is a favorite in our house, and I like that it’s kind of movie themed without being too serious.

The colors work really well with the room, and play well with the over sized engineer print. What is your favorite way to frame/hang art? While I love store bought frames, sometimes, they just won’t work.